In the complex world of semiconductor manufacturing, equipment uptime is critical to productivity. When issues arise, quick resolution is essential—but with global supply chains and specialized expertise scattered across continents, this presents unique challenges. Enter secureWISE, a specialized solution created to address these exact needs. Modern industrial operations are no longer limited by physical boundaries. With the rapid advancements in Industrial IoT (IIoT), securing and optimizing remote equipment monitoring and access has become critical. secureWISE, a sophisticated IIoT platform, is designed to revolutionize how Original Equipment Manufacturers (OEMs) and fabs collaborate by providing a secure, efficient, and real-time remote access solution.

This blog introduces secureWISE and its unparalleled capabilities in securing intellectual property, enhancing equipment performance, and streamlining remote operations for a wide range of industries.

Origins and Purpose

Developed in the early 2000s, secureWISE was designed specifically to manage supplier remote connectivity for the semiconductor industry. It stands unique as the only solution built to address the needs of both equipment suppliers and fabs (semiconductor manufacturing facilities).

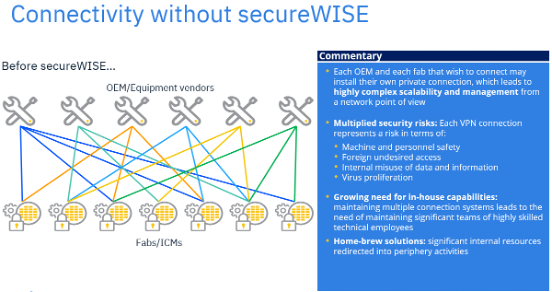

Before secureWISE, the industry faced a fundamental problem: without a neutral intermediary, a patchwork of varying connectivity solutions would have emerged. This scenario would have forced either fabs or equipment suppliers to accept or deny the other party’s solution based on concerns about equipment safety, personnel security, virus proliferation, or potential misuse. The resulting complexity would have been difficult and costly for either party to manage effectively.

The “Single Pane of Glass” Approach

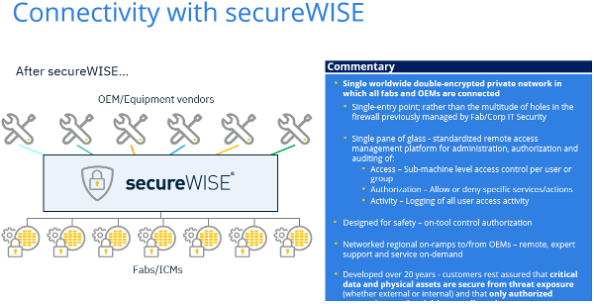

SecureWISE functions on what industry experts call a “single pane of glass” concept—similar to how TSA operates at U.S. airports, funneling all travelers through a single screening point before they proceed to multiple gates.

For semiconductor manufacturers, this means replacing potentially dozens of separate connections from different equipment suppliers with just one secure connection through secureWISE. This dramatically simplifies network management and security oversight. Similarly, equipment manufacturers benefit by establishing just one connection to secureWISE rather than maintaining separate connections to each client fab.

Key Components

The secureWISE platform consists of two major components:

- ServiceNet

ServiceNet is a global private network connecting equipment suppliers and fabs through strategically positioned hubs in key industry locations. This closed network operates primarily through IPsec VPN tunnels, creating an encrypted pathway that serves as the outermost security shield. Only subscribers to secureWISE can access this network, filtering out unwanted traffic that might otherwise reach production environments.

Data flowing through ServiceNet enjoys double-encryption protection:

- IPsec VPN encryption at the network level

- TLS (HTTPS) encryption between end points

- SecureWISE Server

Deployed at each fab site, this server connects to ServiceNet through an IPsec VPN tunnel and serves as a triple-A (Authentication, Authorization, and Audit) server:

- Authentication: Verifies user identity

- Authorization: Controls access permissions

- Audit: Maintains comprehensive logs of user activities, including timestamps for actions like file transfers

The server includes numerous security safeguards, with antivirus protection being particularly noteworthy. All file transfers—whether equipment logs being downloaded for analysis or software updates being deployed to equipment—undergo antivirus scanning before transmission. If malicious code is detected, files are automatically quarantined.

SecureWISE maintains these servers, providing regular updates to the operating system, application software, and antivirus definitions—with virus definitions typically updated daily.

Balancing Security and Productivity

What makes secureWISE valuable is its ability to balance competing priorities:

For fabs:

- Enhanced security and safety

- Improved equipment uptime

- Faster issue resolution

- Centralized access control

For equipment manufacturers (OEMs):

- Uniform connectivity solution across their installed base

- Ability to manage equipment fleet holistically

- Reduced travel time and costs

- Protection of proprietary information

- Faster response to customer issues

Business Impact

The business value of secureWISE extends beyond security. By enabling rapid remote diagnostics and troubleshooting, the platform helps:

- Reduce equipment downtime

- Lower operational costs

- Minimize customer frustration from support delays

- Allow preliminary problem-solving before on-site visits

- Support equipment across vast geographical distances

In semiconductor manufacturing, where production equipment represents massive capital investments and downtime can cost millions, secureWISE plays a vital role in maximizing equipment utilization and factory output.

Find out even more about secureWISE and download a data sheet today!