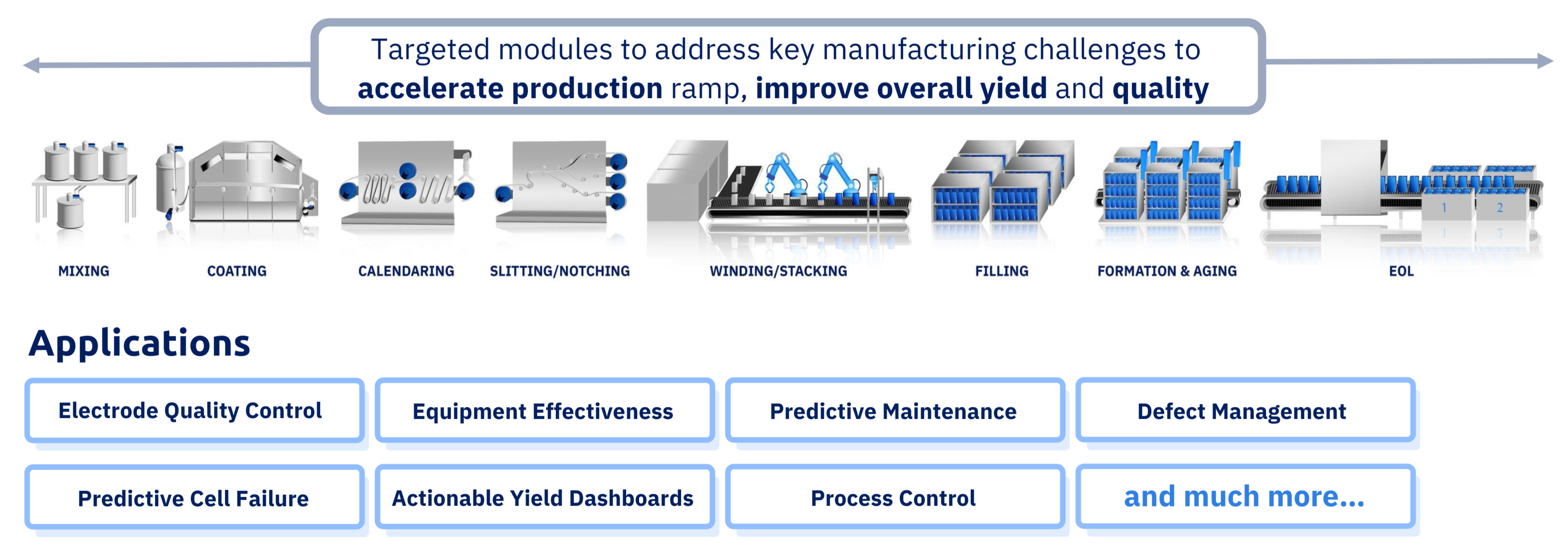

Advanced Analytics for Yield Improvement in Battery Cell Manufacturing

Exensio Battery is engineered to improve yield, reduce scrap, and streamline production through targeted, AI-powered solutions. Our Exensio Battery modules leverage PDF Solutions’ core technologies to address specific challenges in battery cell manufacturing, such as Electrode Quality Monitoring & Control, Defect Management, and Tool-to-Tool Performance Matching. These modules enable manufacturers to improve operational efficiency and enhance product quality.

PDF Solutions has been the trusted partner of semiconductor manufacturers for over 30 years. We have improved yield and helped the largest worldwide fabs bring new products and processes to market from the ground up by helping analyze complex manufacturing data and pinpoint production inefficiencies. Now, we are applying this proven expertise to the battery industry; empowering manufacturers to optimize their processes and achieve higher yields in battery cell production.

Explore Some of Our Unique Modules Addressing the Most Challenging Battery Manufacturing Issues

1. Electrode Quality Monitoring & Control:

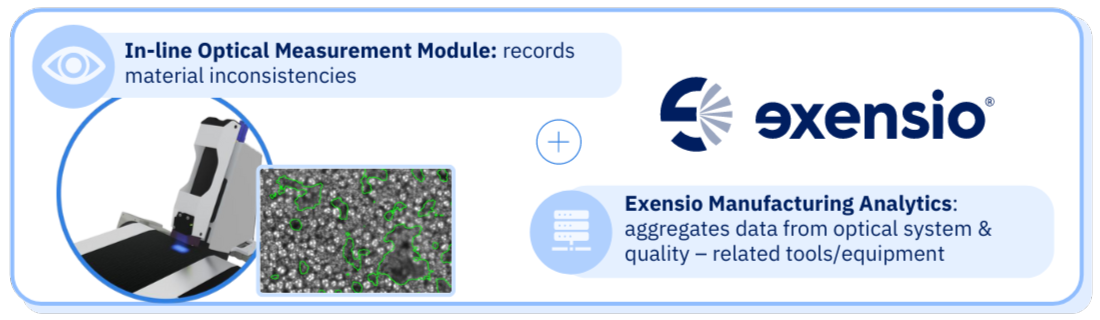

The performance of a cell begins with the quality of the electrode, where even minor inconsistencies in coating dispersion or electrode lane slitting accuracy can lead to significant yield loss. We provide a way for cell manufacturers to monitor and control your electrode quality in-line using our Optical Measurement Module (OMM) & Exensio Manufacturing Analytics.

Our Optical Measurement Module (OMM) is a high-resolution (2-micron) in-line imaging system that captures material characteristics in real time, scanning electrodes at high production speeds after coating, calendaring, or slitting. Powered by advanced AI and machine learning, OMM analyzes critical image features such as coating uniformity, dross formation, contamination, burrs, and surface roughness. For example, surface roughness can lead to Hi-Pot rejects as coating bumps create weak points, resulting in insulation failures. By detecting such defects early, OMM allows manufacturers to address issues before they escalate, reducing the likelihood of rejects and improving overall production quality.

Paired with Exensio Manufacturing Analytics, OMM data is integrated with cell quality data from testing & production to discover key relationships between material metrics and cell quality.

By offering unparalleled visibility into the electrode production process, OMM helps manufacturers detect and resolve defects early, avoiding costly rework or scrap at later stages. This module enables continuous quality monitoring and provides early actionable insights that help maintain process stability and product consistency.

Learn More:

DOWNLOAD the OMM data sheet

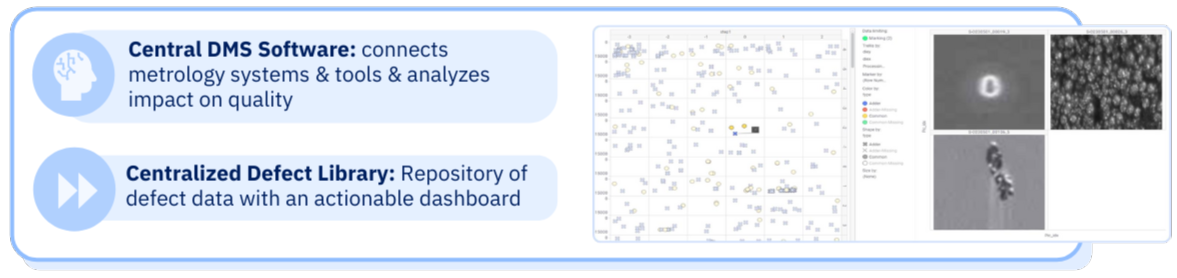

2. Improved QC with integrated Defect Management System (DMS):

Manufacturers often struggle to determine the relevance of cell quality metrics across various vision systems and inspection tools, leading to numerous false & missed rejects. Our inspection system agnostic Defect Management System (DMS) addresses this by centralizing defect data from all cell manufacturers’ inspection tools and production equipment. DMS provides a unified view of defect origins along the electrode roll, stacked electrode, or entire cell, their frequency & type, and their impact on cell performance, helping manufacturers accurately assess which defects truly affect product quality.

On top of routine defect analysis, DMS is also used to identify malfunctioning tools through common pattern identification, helping pinpoint equipment issues early. A key strength of our DMS is its unique ability to trace the genealogy of all defects and align them with substrate size changes—something unmatched in the industry.

This comprehensive approach reduces false rejects and enables more precise, data-driven quality control.

Our DMS allows users to build defect libraries that categorize, and rank defects based on their influence on product quality. For example, surface contamination may significantly increase self-discharge rates, whereas minor variations in thickness might have negligible effects.

The system provides deep insights into where and how defects affect yield, enabling manufacturers to adjust quality metrics, fine-tune processes, and reduce both false rejects and escapes.

DOWNLOAD the DMS for Battery data sheet

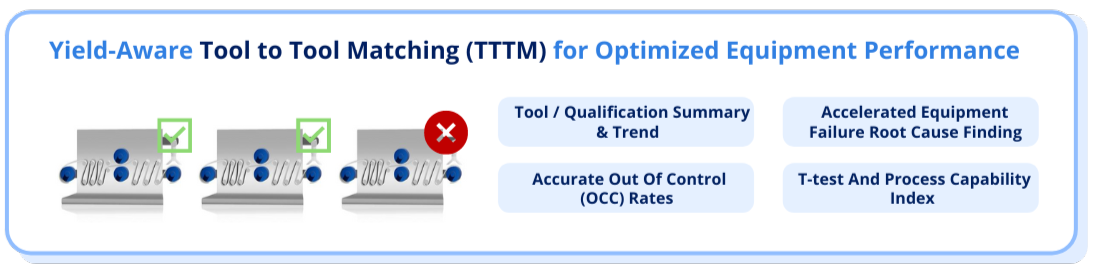

3. Yield-Aware Tool-to-Tool Matching (TTTM):

Maintaining consistency between tools across production lines is a critical challenge in medium to large-scale manufacturing. Yield-Aware Tool-to-Tool Matching (TTTM) (powered by Exensio Manufacturing Analytics), as part of our overall TTTM offer, enables manufacturers to compare tools based on their impact on yield rather than relying on subjective or experience-based methods. TTTM selects a “golden tool” and fingerprints key characteristics to achieve high yield, allowing manufacturers to benchmark other tools against it to ensure consistency efficiently in production.

This solution goes beyond simple equipment matching by using advanced algorithms to analyze tool data at a granular level. TTTM performs in-depth statistical comparisons, including t-tests and process capability analyses, to identify variations that could affect yield. This allows for data-driven decisions when adjusting tools or performing maintenance, ensuring that all tools operate at peak performance and minimizing the risk of yield loss due to tool mismatches.

TTTM also facilitates long-term trend analysis and generates detailed reports for continuous improvement and operational optimization.

Explore More Solutions

In addition to these key modules, Exensio Battery offers a comprehensive suite of tools designed to address various critical challenges in battery manufacturing, from process control to advanced analytics. Our platform also includes AI/ML ModelOps solutions with a ready-to-go infrastructure for training, deploying, and monitoring both PDF’s models and customers’ own models.

Our flexible platform allows manufacturers to customize & enhance solutions based on their specific needs, ensuring optimal performance and yield improvement at every stage of production.

To learn more about our full range of modules and how they can help you tackle your manufacturing challenges, contact us today.

Integrated Solutions Across the Production Line

For an overview of how our solutions work together to address battery manufacturing issues across the manufacturing line, watch our video below.