The semiconductor industry operates at the forefront of technological innovation, even as manufacturers face constant pressure to improve production yields, manage intricate supply chains, reduce costs and accelerate time to market.

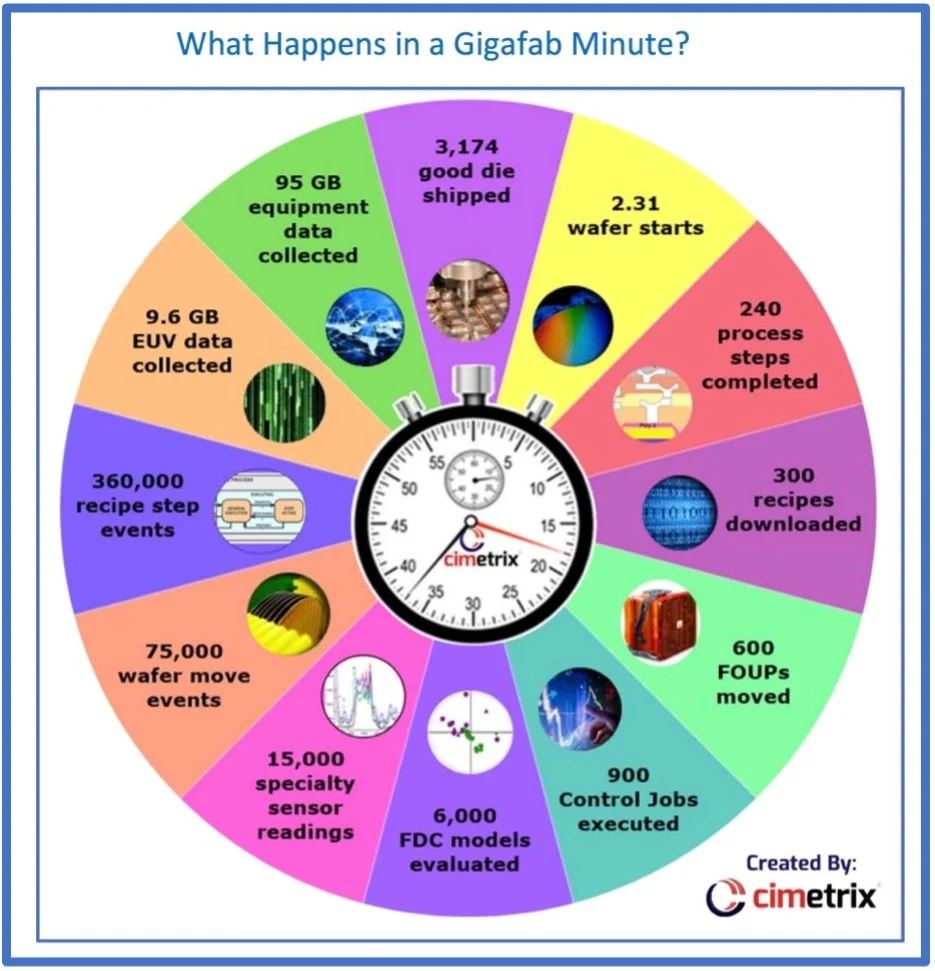

What happens in gigafab minute?

The volume of data generated by the semiconductor manufacturing process is such that the management and curation of that data set is a challenge in itself. In 1 minute of a gigafab manufacturing process, there are 75,000 wafer move events, 15,000 sensor readings, 9.6 GB of EUV data collected, 95 GB of equipment data collected, and 360,000 recipe step events.

Data is the bedrock of AI

Data is the bedrock upon which artificial intelligence (AI) is built. AI systems learn and improve by analyzing vast amounts of data, identifying patterns, and making predictions. Without quality data, AI systems will be limited in their ability to perform effectively. But to make sense of the massive amount of semiconductor manufacturing data coming from different types of tools and sources and at different frequencies it is necessary to clean and align all the data elements on common definitions and data standards. Doing this requires a semantic definition of what the data elements are and their relationship in the context of an overall semiconductor fab data model.

The Exensio Manufacturing Analytics Solution

At its core of the Exensio solution provides manufacturers with the ability to access, organize and analyze manufacturing data with unmatched precision. By doing so, manufacturers can reduce costs, accelerate new product introduction, achieve higher yields and improve product quality. It can create digital twins, virtual representations of physical manufacturing processes built by collecting vast amounts of data, including tool information, defect data, equipment history, assembly metrics and system-level insights. This information is structured using a semantic data model, which captures the complex relationships between data points.

What is the semiconductor manufacturing semantic data model?

Semantic data models help to ensure data completeness and quality across the manufacturing lifecycle. Integrating information such as material metadata, defect data and equipment usage history, semantic models enable engineers and decision-makers to:

- Identify patterns and correlations across processes.

- Predict production outcomes with greater confidence.

- Uncover opportunities to optimize resources.

By associating event data with metrology results, manufacturers can proactively address issues before they impact yield or quality through the solution’s:

- Comprehensive Manufacturing Lifecycle Coverage. Operational silos are eliminated by offering end-to-end visibility across multiple stages of manufacturing. From design to final assembly, its functionality spans geographically distributed supply chains, enabling streamlined decision making across the enterprise.

- Advanced Analytics and AI Integration. AI and ML capabilities extract actionable insights from complex datasets for faster yield ramp-ups, excursion prevention through fault detection and classification and predictive analytics for equipment utilization and maintenance.

- Real-Time Data Collection and Organization. Robust connectivity solutions collect massive volumes of data in real-time from over 40,000 process control tools and 55,000 fab tools. This real-time access allows manufacturers to continuously monitor production health continuously, capture granular data for enhanced precision, and make immediate, impactful adjustments to processes.

- Enhanced Supply Chain Traceability. Facilitates seamless integration between manufacturing facilities and enterprise systems, such as enterprise resource planning (ERP) solutions for superior product quality and compliance with evolving standards.

Addressing Key Semiconductor Manufacturing Challenges

The platform addresses some of the most pressing issues in semiconductor production and manufacturers report improved yield and quality. On average, device yields improve up to 10%, low-yield tails are reduced by up to 20% and product quality reaches levels of less than one defect per million parts. They can reduce time to market by 30% faster yield ramps than industry averages.

Other benefits of data-driven analytics platforms can:

- Break Data Silos. Traditional manufacturing environments often suffer from data silos that inhibit decision-making. A unified semantic data model consolidates disparate data sources, empowering teams with integrated insights.

- Boost Equipment Utilization. Predictive analytics and actionable insights can lead to a 20% improvement in test or equipment utilization, resulting in reduced operational waste and better ROI.

- Enhance Engineering Efficiency. By automating diagnostics and providing intelligent recommendations, engineering teams can boost productivity by as much as 5X, allowing for more focused innovation and process refinement.

Real-World Impact

Manufacturers leveraging the platform report its impact. In one instance, a leading foundry achieved a 20% reduction in costly excursions caused by production anomalies after implementing fault detection capabilities. In another, an outsourced semiconductor assembly and test (OSAT) provider reduced parametric yield variation by 15%, leading to faster deliveries and better business margins.

Other manufacturers describe faster Issue resolution by combining fault detection with advanced analytics mitigates false alarms and resolves production issues before they escalate. Optimized tool utilization and reduced scrap lead to cost reductions throughout the production process while improved product quality at scale ensures fewer defects, bolstering customer trust and loyalty.

New capabilities announced throughout 2025 will take advantage of the AI evolution, transitioning from traditional data analytics to deep learning for more advanced insights. Enhanced scalability will support ultra-high-volume manufacturing with faster processing capabilities and improvements to the user experience with analytics-driven interface upgrades while collaborations with industry leaders will develop innovative AI-enabled applications.

Smarter, Data-Driven Approaches to Manufacturing

The increasingly competitive semiconductor industry demands smarter, more data-driven approaches to manufacturing. With state-of-the-art analytics, AI capabilities and robust data integration, PDF Solutions’ Exensio solution provides manufacturers with the tools needed to excel in a rapidly evolving landscape enabling visibility across the entire production lifecycle and delivering measurable results.

For more information, please visit:

https://www.pdf.com/products/exensio-analytics-platform/overview/

https://www.pdf.com/pdf-solutions-platform-for-semiconductor-analytics-download/