DMS for Battery Data Sheet

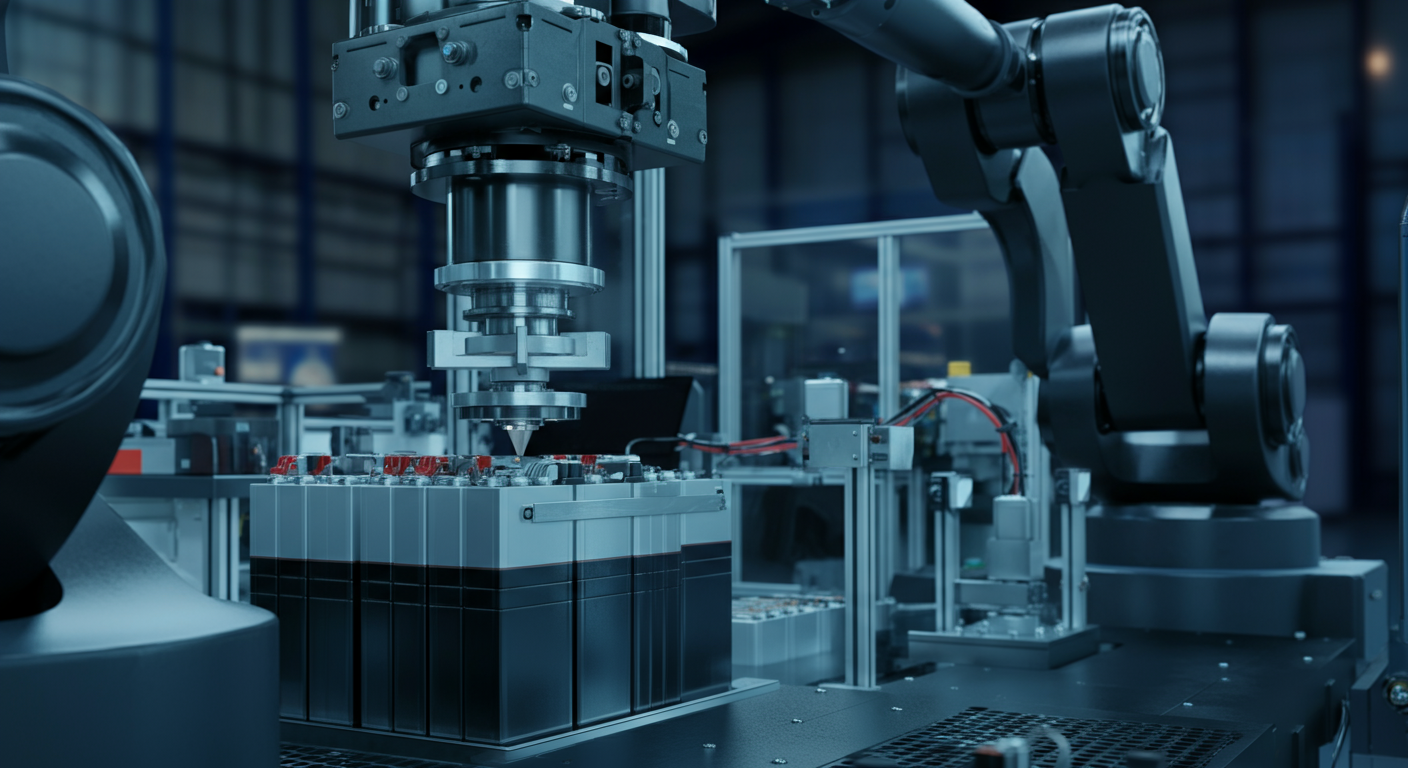

Our Defect Management System (DMS) streamlines battery manufacturing by integrating defect data from various sources into a centralized, organized platform. Using AI-driven analytics, DMS applies Automated Defect Classification (ADC) to extract and categorize defects, reducing false rejects and enabling manufacturers to identify critical defect trends. By providing a structured, data-driven approach to defect analysis, DMS enhances decision-making, improves yield, and strengthens process control across the production line.

The system includes a defect map and analysis tool to store and analyze defect data, visualizing defects by lot, cell, and electrode roll while incorporating inline system images for better classification.

The defect map groups similar defects by type, providing Kill Rate and Capture Rate summaries and distinguishing between common and uncommon defects for focused analysis.

Integrated with the client’s Manufacturing Execution System (MES), it defines Statistical Process Control (SPC), Out-of-Control Action Plans (OCAP), and sends real-time alarms for monitoring.

By downloading this information I agree that PDF Solutions, Inc. may use my information provided herein to contact me about its products and services, even if I have previously unsubscribed from such communications. For information on our privacy practices and commitment to protecting your privacy, please review our Privacy Policy.