Dynamic Configuration

Easily configure your equipment to support variations or entire families of equipment types. The dynamic flexibility of CIM300 ensures scalability and adaptability across multiple systems without additional complexities.

Configure CIM300 dynamically to support equipment variations or entire equipment families with ease. Scale and adapt across systems without added complexity.

Simplified API Framework

Complex manufacturing scenarios, including carrier and slot map verification, are reduced to a few API calls. This framework saves valuable engineering time and reduces the margin for error during integration.

Implement complex manufacturing scenarios, such as carrier and slot map verification, using only a few API calls. This framework saves engineering time and minimizes integration errors.

Modular GEM300 Standards Implementation

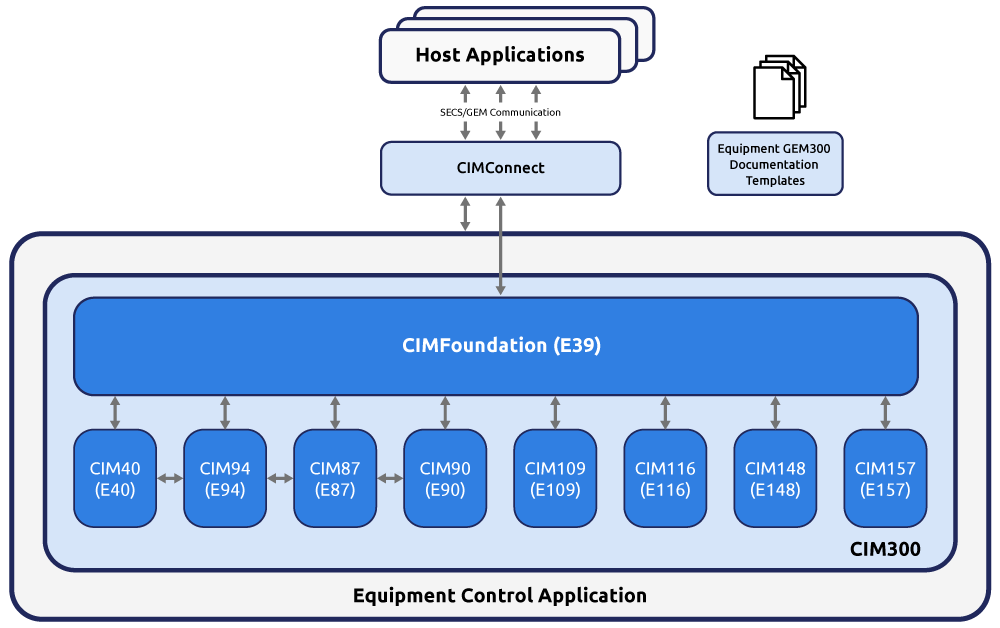

CIM300 allows you to implement GEM300 standards either as a full suite or independently. For instance, you can run E90 (Substrate Tracking) without E87 (Carrier Management) or E40 (Process Job) without E94 (Control Job), offering unmatched flexibility for backend operations.

Deploy GEM300 standards as a complete, integrated suite or selectively implement only the components you need. With CIM300’s modular architecture, you can activate features like E90 (Substrate Tracking) without E87 (Carrier Management), or E40 (Process Job) without E94 (Control Job)—delivering the flexibility to tailor your solution to specific operational requirements.

Product Reliability and Maturity

Built on Cimetrix CIMConnect, a trusted leader in SEMI SECS/GEM standard compliance, CIM300 delivers a robust and mature solution that supports multiple integrated features accepted across all 300mm fabs worldwide.

Rely on a robust, proven solution built on Cimetrix CIMConnect. CIM300 is trusted across global 300mm fabs for SEMI SECS/GEM standard compliance.

What is Cimetrix CIM300?

What is Cimetrix CIM300?