The Software Framework for Equipment Automation

Optimize your equipment control application development and boost reliability with Cimetrix CIMControlFramework (CCF)–a robust software development kit designed to standardize and accelerate the creation of equipment control solutions. CCF empowers you to implement factory automation, supervisory control, material handling, and operator interfaces, while leveraging your in-house expertise.

Optimize your equipment control application development and boost reliability with Cimetrix CIMControlFramework (CCF)–a robust software development kit designed to standardize and accelerate the creation of equipment control solutions. CCF empowers you to implement factory automation, supervisory control, material handling, and operator interfaces, while leveraging your in-house expertise.

What is CIMControlFramework?

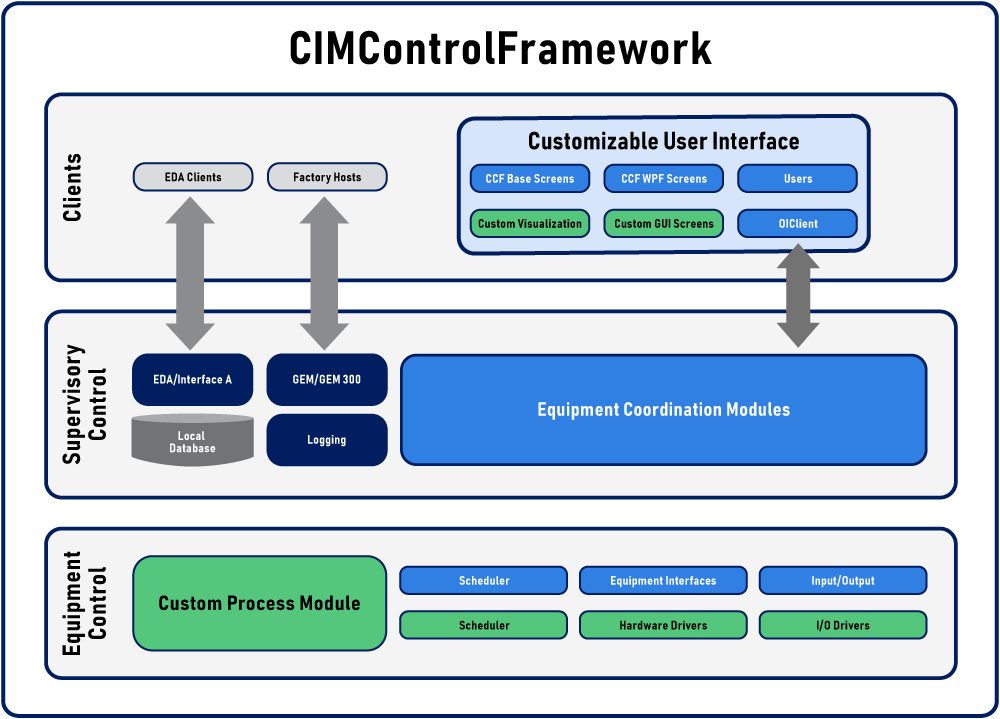

CIMControlFramework is a leading equipment automation framework built on Microsoft .NET technology for advanced supervisory control and seamless factory integration. Engineered for manufacturers navigating the complexities of equipment control, CCF incorporates built-in support for SEMI Standards (SECS/GEM, GEM300, and EDA/Interface A) for superior interoperability.

With a modular, extensible, and customizable architecture, CCF minimizes development times, enabling you to channel resources toward your core technologies. Its advanced logging capabilities and LogViewer application simplify diagnostics, allowing remote troubleshooting and reducing downtime. CCF source code, where available, puts manufacturers in full control of optimizing equipment performance and enabling long-term, customizable solutions.

Designed for unrivaled flexibility and stability, CCF ensures that even the most complex environments are handled effectively by enabling seamless transitions between existing systems and new implementations.

DOWNLOAD the CIMControlFramework datasheet