Ensure Equipment GEM Compliance and Optimize Factory Integration with Comprehensive SECS/GEM Testing

What is EquipmentTest?

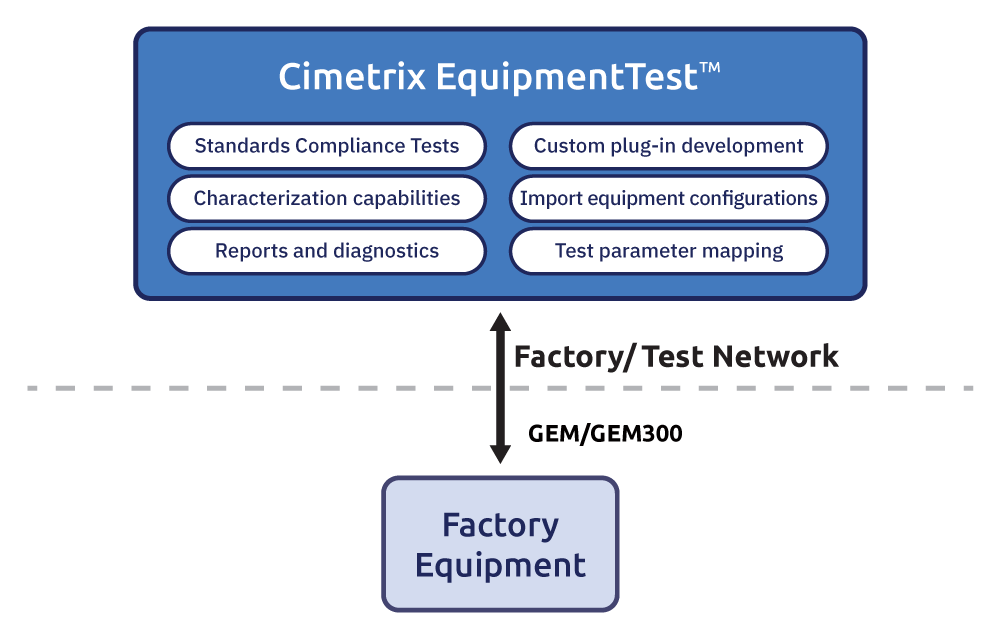

Cimetrix EquipmentTest™ is a comprehensive SECS/GEM testing solution engineered to validate equipment interface compliance with SEMI standards and streamline integration with factory host systems. Built on the Microsoft Test Runner framework, EquipmentTest offers reliable and scalable testing capabilities for both basic and advanced GEM interface validation.

The Pro version extends functionality by enabling users to create and deploy custom test scenarios using C#, offering enhanced flexibility for complex validation and automation workflows. The Pro version provides GEM equipment characterization functionality by executing GEM scenarios through the user interface without having to know SECS-II message details.

DOWNLOAD the EquipmentTest Datasheet

Key Features of EquipmentTest

Comprehensive Standards Testing

- GEM Compliance Testing: Perform full SEMI E30 compliance testing with automated reporting.

- Silent GEM Compliance: Run compliance tests without operator interaction to support automated workflows.

- Basic Validation Test: Verify GEM interface connectivity and operational status quickly.

- Automatic Mapping: Configure screens and tests automatically based on GEM implementation features.